RF-HY18R

RS485, RS232

| Availability: | |

|---|---|

| Quantity: | |

| Parameter | Specification |

| Minimum Order Quantity | one |

| Price | receive bargaining |

| Delivery Time | 5-8 Work Days |

| Stock | In Stock |

| Description | RFID read/write head HF, external diameter M18*92mm, 13.56MHz |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |

| product model | RF-HY18RL-R4 | RF-HY18RL-R2 | RF-HY18RL-IOL |

| wireless protocol | ISO15693/ISO14443A | ||

| Operating frequency [MHz] | 13.56MHz | ||

| output power | 27.5dBm | ||

| wireless speed | 26.48Kbit/s | ||

| Distance write/read head [mm] | 0~30mm(Related to the loaded code body) | ||

| communication interface | RS485 | RS232 | IOLink |

| communication protocol | MODBUS RTU | IOLink V1.1 | |

| Communication rate | 9600~115200bit/s | 230kbps | |

| mains input | 9-30VDC | ||

| average current | <0.05A@24VDC | ||

| indicator light | 1 LED indicator | ||

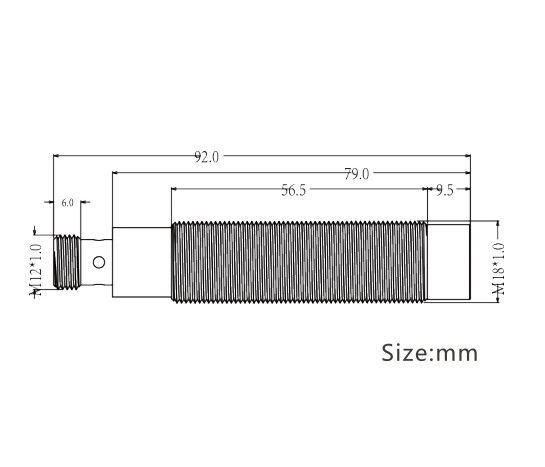

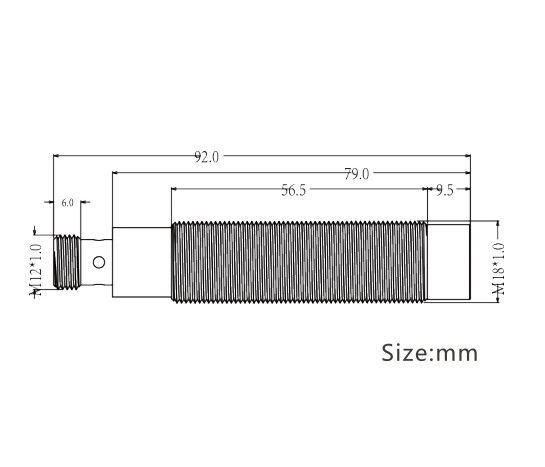

| boundary dimension | M18*92mm | ||

| Product interface | M12 Acode 4PIN male head | ||

| fixture type | Nut fixed, screw tooth M18*1.0 | ||

| canning material | Brass plated with nickel +ABS | ||

| Shell color | Silver + Black | ||

| total weight | 50g | ||

| operating temperature | ~25℃~+70℃ | ||

| storage temperature | ~25℃~+85℃ | ||

| humidity | 5%~95%RH(without condensation) | ||

| Waterproof and dustproof grade | IP67,EN 60529 | ||

| Resistance to vibration | 2 mm (f= 5…29.5 Hz ) , | ||

| EN 60068-2-6 | |||

| 7 gn (f= 29.5…150 Hz) , | |||

| EN 60068-2-6 | |||

| Conduction immunity (CS) | 3V, Class A (including main frequency) | ||

| 10V, Class A (except main frequency) | |||

| Electrostatic discharge immunity ESD | Contact discharge, 8KV, Class A air discharge, | ||

| 15KV, class A IEC61000-4-2 | |||

| Certificate | CE | ||

| FCC | |||

| ROHS instruct | 2011/65/EU,2015/863/EU | ||

| Parameter | Specification |

| Minimum Order Quantity | one |

| Price | receive bargaining |

| Delivery Time | 5-8 Work Days |

| Stock | In Stock |

| Description | RFID read/write head HF, external diameter M18*92mm, 13.56MHz |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |

| product model | RF-HY18RL-R4 | RF-HY18RL-R2 | RF-HY18RL-IOL |

| wireless protocol | ISO15693/ISO14443A | ||

| Operating frequency [MHz] | 13.56MHz | ||

| output power | 27.5dBm | ||

| wireless speed | 26.48Kbit/s | ||

| Distance write/read head [mm] | 0~30mm(Related to the loaded code body) | ||

| communication interface | RS485 | RS232 | IOLink |

| communication protocol | MODBUS RTU | IOLink V1.1 | |

| Communication rate | 9600~115200bit/s | 230kbps | |

| mains input | 9-30VDC | ||

| average current | <0.05A@24VDC | ||

| indicator light | 1 LED indicator | ||

| boundary dimension | M18*92mm | ||

| Product interface | M12 Acode 4PIN male head | ||

| fixture type | Nut fixed, screw tooth M18*1.0 | ||

| canning material | Brass plated with nickel +ABS | ||

| Shell color | Silver + Black | ||

| total weight | 50g | ||

| operating temperature | ~25℃~+70℃ | ||

| storage temperature | ~25℃~+85℃ | ||

| humidity | 5%~95%RH(without condensation) | ||

| Waterproof and dustproof grade | IP67,EN 60529 | ||

| Resistance to vibration | 2 mm (f= 5…29.5 Hz ) , | ||

| EN 60068-2-6 | |||

| 7 gn (f= 29.5…150 Hz) , | |||

| EN 60068-2-6 | |||

| Conduction immunity (CS) | 3V, Class A (including main frequency) | ||

| 10V, Class A (except main frequency) | |||

| Electrostatic discharge immunity ESD | Contact discharge, 8KV, Class A air discharge, | ||

| 15KV, class A IEC61000-4-2 | |||

| Certificate | CE | ||

| FCC | |||

| ROHS instruct | 2011/65/EU,2015/863/EU | ||

13.56MHz operating frequency, support ISO15693 and ISO14443A protocols, communication mode CAN RS485, IO-Link, CAN, support MODBUS RTU, IO-Link, CANOPEN protocols, easy to integrate

Brass nickel-plated shell, IP67 protection grade, can be applied to oil, dust, wet harsh conditions

Power supply with over current and over voltage protection and filtering function, can be applied to harsh electromagnetic interference environment

Using 2 nuts to fix, small and diverse size, suitable for the size requirements are relatively high, precision manufacturing links to automatic identification scenes.

Products in process/tooling fixtures/fixtures/accessories are installed or embedded with RFID code tags.

RFID reading and writing devices are deployed on the stations of automated nodes, and multi-variety

and large-scale production methods are realized through interaction with products in process, automatic

Real-time identification of single-grade products, automatic series automation equipment and robots, and

personalized process transmission are realized. Scenarios such as automatic parameter definition and

automatic device detection.

13.56MHz operating frequency, support ISO15693 and ISO14443A protocols, communication mode CAN RS485, IO-Link, CAN, support MODBUS RTU, IO-Link, CANOPEN protocols, easy to integrate

Brass nickel-plated shell, IP67 protection grade, can be applied to oil, dust, wet harsh conditions

Power supply with over current and over voltage protection and filtering function, can be applied to harsh electromagnetic interference environment

Using 2 nuts to fix, small and diverse size, suitable for the size requirements are relatively high, precision manufacturing links to automatic identification scenes.

Products in process/tooling fixtures/fixtures/accessories are installed or embedded with RFID code tags.

RFID reading and writing devices are deployed on the stations of automated nodes, and multi-variety

and large-scale production methods are realized through interaction with products in process, automatic

Real-time identification of single-grade products, automatic series automation equipment and robots, and

personalized process transmission are realized. Scenarios such as automatic parameter definition and

automatic device detection.